The difference between heat shrinkable tubing and cold shinkable tubings

1、 Usage:

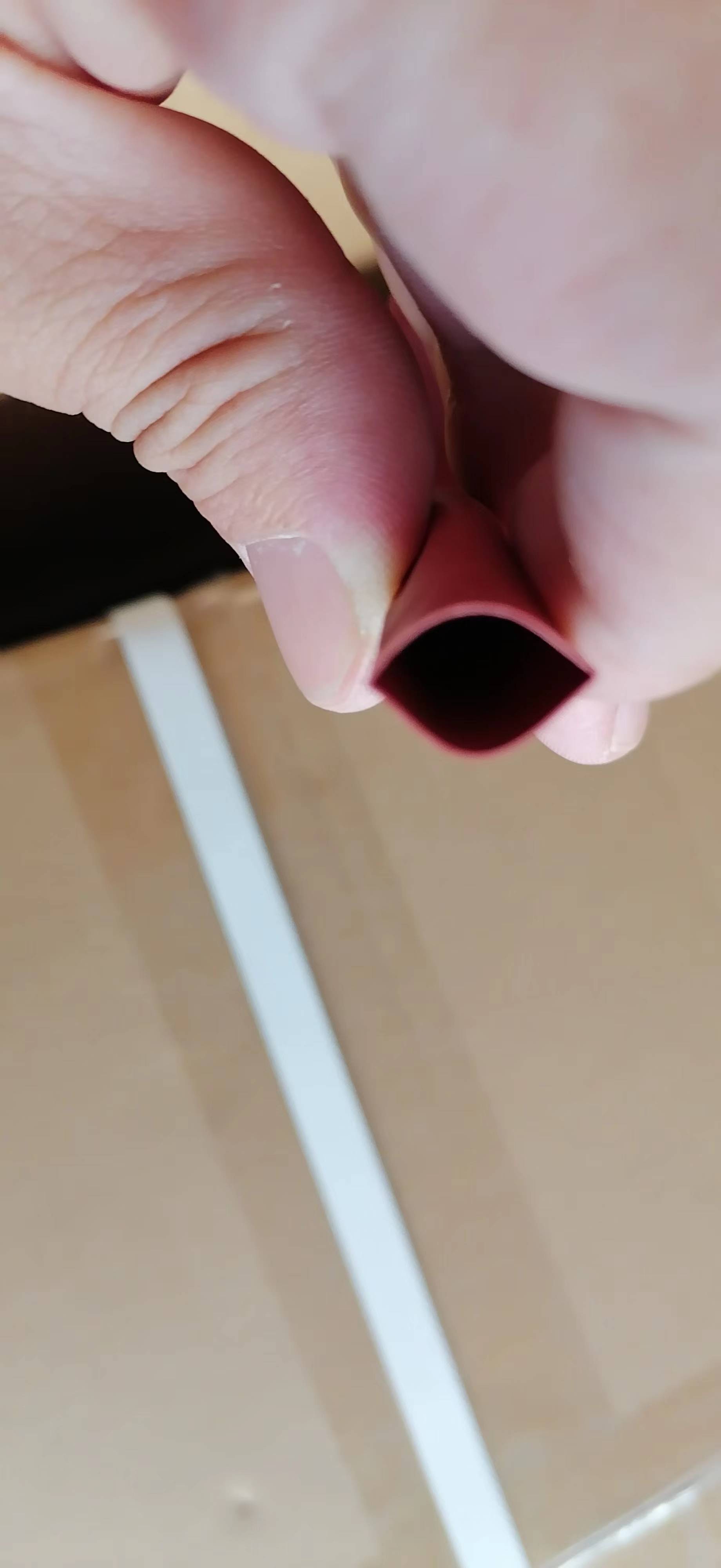

Cold shrink tube: easy to install and stretch on the removable plastic core, allowing the sleeve to slide on the application. After the plastic support is removed, the sleeve starts to shrink, playing a sealing and protection role around the cable or connecting parts. At present, the materials of cold shrink tubes are basically ethylene propylene diene monomer (EPDM) rubber or silicone rubber.

Heat shrinkable tube: select a suitable heat shrinkable tube, cover it on the wire connector, heat it with a hot air gun and other heat sources, and then shrink the heat shrinkable tube when it is heated, and then cover the connector firmly.

2、 Physical properties:

Compared with heat shrinkable tubes, cold shrinkable tubes have excellent weather resistance, UV aging resistance and higher brittleness resistance. It is simple and safe to install without tools or special training. No cutting torch or heat source is required.

Heat shrink tubing is resistant to most chemicals and, once heated, becomes very rigid, making it a good choice for mechanical protection. However, the disadvantage of this rigidity is that the product cannot expand and contract with the cable, which means that the environment cannot be sealed without the help of hot melt adhesive or adhesive tape.

3、 Main purpose:

Cold shrinkable pipe: the main electrical insulation of all solid insulated (rubber and plastic) insulated wires and cable joints with a rated voltage of 1000 V complies with ANSI C119.1, and can be laid underground or underwater, for indoor, outdoor or overhead use.

Heat shrinkable tube: It is not applicable to the installation area with high temperature or high humidity, but it is applicable to most industrial/commercial equipment and places where chemical resistance is required.